In today’s business climate, data centre operators and users are constantly striving for two goals; higher availability and lower energy consumption.

An extremely effective way of improving availability is to introduce redundancy; accordingly, this technique is widely deployed at all infrastructure levels, from entire data centres down to device-level strategies within them. In this article, Ian Jackson Managing Director at KOHLER Uninterruptible Power (Ireland), introduces this ubiquitous technique, and then discusses how it can be optimised within UPSs, using modular topology, to improve data centre power availability.

As significant power components, UPSs impact data centre energy efficiency as well as availability. Accordingly, we will see how the modular topology used to improve UPS availability also increases efficiency.

Availability at all levels

According to a recently-released Uptime Institute Intelligence report, ‘Annual Data Center Survey Results 2019’, distributed resiliency using active-active data centres is becoming more common. 40 percent of those surveyed said they use availability zones for resiliency – a strategy that requires at least two active data centres replicating data to each other.

Active-active strategies are also found at server level, where they are implemented using server clustering. To the clients, the cluster behaves as a single server with one IP address. While active-passive configurations are possible, where one server or node is on line while others stand by, active-active solutions, where each node shares the workload, are increasingly preferred. These offer more computing capacity as multiple servers are available for processing, while also providing redundancy; if one server fails, the others continue operating and servicing the critical load without interruption.

Improving availability through redundancy has always been available for UPS installations, even before the advent of modular designs. A load of 400 kVA, for example, could be supported by a single 400 kVA monolithic UPS system to provide capacity-only protection. Alternatively, two such units could support the load with N+1 redundancy. However, this means that the user had to invest in double the UPS capacity that they really needed – an unwelcome addition to their capital costs, as well as to real estate demand within the data centre. Additionally, neither unit can ever be more than 50 percent loaded – and with the transformer-based technology typically found in such monolithic systems, this severely impacts operating efficiency and increases the cooling load. So operating costs, as well as capex, are significantly increased.

The arrival of modular UPS systems resolved these issues. Advances in semiconductor technology allowed uninterruptible power systems to be implemented as transformerless modules small and light enough to be slotted incrementally into a standard 19” rack rather than installed as immobile floor-standing units. The 400 kVA load of the above example could be met with a KOHLER Uninterruptible Power KOHLER PW 9500DPA rack as in Fig.1, populated with four 100 kVA modules – or with five, to provide N+1 redundancy. Only 20 percent, rather than 50 percent of the total capacity is needed for the same redundancy result. Floorspace demand and capital expenditure are reduced, as are energy and air-conditioning costs.

Fig.1: KOHLER PW 9500DPA – a modular 100 – 500 kVA UPS

Another crucial aspect of modular systems such as the KOHLER PW 9500DPA is their hot-swap capability. A faulty module can be removed and replaced without shutting down the UPS or interrupting power to the critical load. Repairs can be completed typically within half an hour, compared with the six hours or so more usually needed to repair a monolithic system in situ. This system also has the advantage of being fully decentralised meaning there is no common logic or static bypass therefore no single point of failure unlike centralised Modular systems.

As a result, modular systems can offer ‘six nines’ or 99.9999 percent availability, compared with 99.9995 percent for the legacy solution.

Modularity improves efficiency too

Transformerless modular systems offer efficiency improvements over their transformer-based counterparts partly through their technology’s inherently better efficiency, but also because they can be so closely matched to their critical load – this means they can be kept more fully-loaded, and in the optimal part of their efficiency curve.

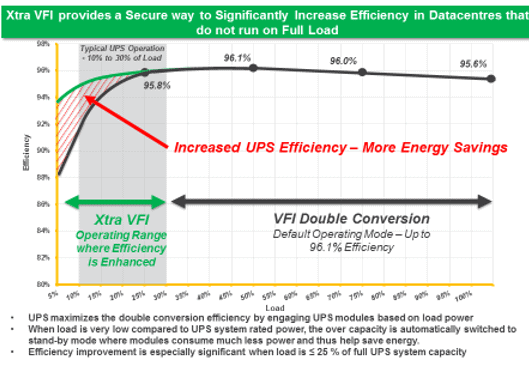

However, load levels in data centres can be both unpredictable and dynamic, so a UPS, either temporarily or for longer periods, could find itself severely underloaded – and if load levels drop below 25 percent, even modular system efficiency starts to fall off.

This can be avoided by using Xtra VFI technology, which automatically adjusts the number of active modules to meet current load requirements. Excess modules are switched to standby, but remain primed to transfer to active mode if the load increases. Fig.2 shows how the Xtra VFI operating mode can enhance efficiency when running at a low load level for a KOHLER PW 9500DPA modular UPS system, with 10 UPS modules (100kW) and total available capacity of 1 MW.

Fig.2: How Xtra VFI improves UPS efficiency on low load

Conclusion

We have seen how modular topology improves both UPS availability and efficiency. However, to achieve these results in practice, the underlying hardware must be of robust design and construction, and professionally and regularly maintained. Accordingly, it’s essential to discuss your power protection requirements with a reputable, well-resourced and experienced supplier such as KOHLER Uninterruptible Power to avoid risk of a UPS failure and its consequences for profitability, business continuity and reputation.