Cloud services are attractive to their users partly because they can be based in data centres that offer levels of security that cannot be matched by an enterprise’s own facilities. To achieve these levels of security, the cloud data centres’ ICT hardware must be supported by UPS systems offering very high levels of availability.

In this article, Ian Jackson, of KOHLER Uninterruptible Power, a KOHLER company, looks at the advanced UPS technology that provides the availability levels required, along with the flexibility, scalability and power efficiency also essential to such operations.

As CTO at Amazon, Werner Vogels believes the cloud has become the driver for tremendous innovation in all companies. Beneficiaries – and their users – range from startups like Dropbox and Pinterest to large enterprises such as Samsung and Unilever and government, education and research institutes. Through their specialist focus and economies of scale, cloud services offer levels of physical and electronic security that often cannot be matched by an enterprise’s on-site facilities.

These security requirements, which are fundamental to cloud services’ role, typically drive service providers to offer data centres with Tier 4 capabilities, where all IT equipment is dual-powered, and the facility is fully fault-tolerant. The centres must be flexible and scalable, to effectively support multiple clients with unpredictable growth or reduction in demand. Facilities on this scale must also be highly energy efficient to contain electricity costs, comply with legislation and preserve the operating company’s reputation.

The overall site tier rating depends on all aspects of the site’s infrastructure, encompassing power and UPS systems, cooling and distribution as well as the ICT equipment itself. This rating equals that of the lowest contributing infrastructure component. The Uptime Institute has assigned a target availability level to each tier as a key aspect of the tier’s rating. Accordingly, the availability of any UPS system included on site must be as high as possible to preserve the facility’s overall tier rating.

Resilience to failure, and availability

Fortunately, UPS technology and topology developments allow data centre operators to configure power protection solutions that offer very high availability along with the levels of flexibility, scalability and energy efficiency they seek. As we will see, resilience to failure can be provided by building redundancy into the UPS design, while availability can be very significantly increased by using a suitable form of modular configuration.

UPS system redundancy depends conceptually on connecting a number of modules in parallel, irrespective of the technology used within the modules. For example we can refer to N+1 redundancy, where N represents the number of modules required to fully support a given critical load. If any single module fails, the others, between them, still have sufficient capacity to fully support the load – and allow repairs to be effected – without any interruption of power.

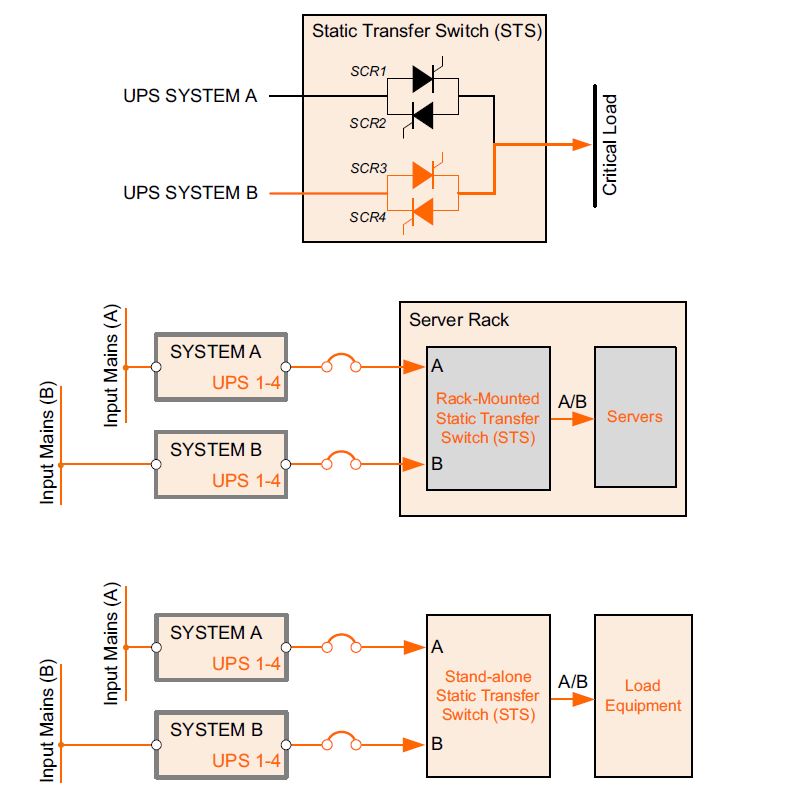

If greater security is required, an N+2 solution can be configured, which tolerates two modules failing simultaneously. Another concept, which should be mentioned in connection with Tier 4 data centres is 2N redundancy. From the data centre’s perspective, 2N does not refer to the UPS topology, but instead to an arrangement in which the critical load is fed by two completely independent power lines, each supported by their own entirely separate UPS system.

Fig.1 below shows a redundant UPS system comprising three modules connected directly to the critical load. This is an N+1 redundant system if the load is, say, 200 kVA and the modules are 100 kVA each. During normal operation the load is shared equally, with each module supplying just under 67kVA. If one module fails, power delivery continues without interruption as the two remaining modules supply 100 kVA each. Note that this a ‘de-centralised parallel architecture’; so-called because no single central point of failure exists in the UPS power path. Each UPS module has its own static bypass switch, which automatically isolates it from the critical load if it develops a fault.

De-centralisation means some duplication of control and switching components as each UPS module has its own static bypass switch. However, centralised systems require a central static switch (CSS) to manage the power path to the critical load. This typically requires a separate cabinet, making the system larger, more complicated to install and more expensive than its de-centralised counterpart. When these factors are considered together with the de-centralised system’s elimination of single points of failure, the popularity of de-centralised architectures becomes obvious.

While most UPS types can be organised in a redundant, fault-resilient modular configuration, the real gains in UPS availability come from hot swap capability and reduction in MTTR. Such attributes have ultimately been made possible through advances in semiconductor technology and the introduction of the Insulated Gate Bipolar Transistor (IGBT) device.

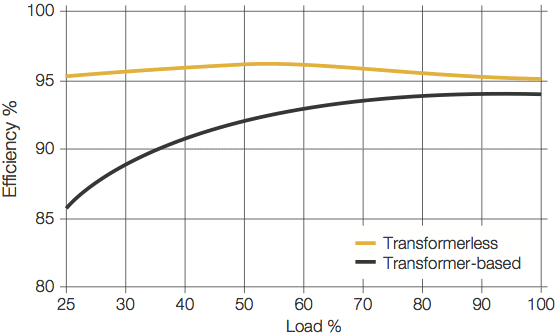

These have allowed the elimination of the step-up output transformer and with it a considerable proportion of the UPS’s size and weight. For example a typical three-phase 50 kVA transformer-based system excluding batteries weighs 400 Kg, whereas a modern equivalent transformerless implementation is just 60 Kg. Sizing is also greatly reduced, so the smaller, lighter UPS modules can be built as plug-in components added to a UPS frame rather than fixed, floor standing units.

A key benefit of hot swappable modules is that they can be inserted or withdrawn without removing power from the critical load or transferring the load to the raw AC mains. If correctly designed, their connectors allow safe electrical connection and disconnection, while safe disconnection from the UPS frame without risk of error or damage to the module, UPS or critical load is possible.

Another equally important benefit is that a faulty module can be quickly exchanged for a healthy unit in as little as half an hour; after this, the UPS is back to full redundant capacity while the faulty module is taken away for repair without time pressure. By comparison, effecting repairs in situ on a free-standing UPS typically takes 6 hours. As a result, hot swappable modular UPS systems improve availability by a factor of 10 compared with free-standing non-modular systems that are not hot-swappable.

Scalability and efficiency

UPSs with a modular design also offer data centre operators the flexibility and scalability they need, whether they are a Cloud facility for a large customer base or a private resource for their own business operation. Fig.2 shows a system that could start with a capacity of 100 kVA and scale to an eventual limit of 3MVA.

Each frame in the image has ‘vertical scalability’; this allows it to accept up to five 100 kVA modules which can be in any N+n redundancy configuration. The ability to parallel up to six frames as shown is known as ‘horizontal scalability’. As the data centre capacity and demand for power grows, new modules can be added incrementally as needed without increase of footprint, cabling or structural installation effort. Additionally, no capital is tied up in speculative future UPS capacity requirements.

Because of its constituent modules’ transformerless design, the UPS shown offers an efficiency improvement of around 5% compared with transformer-based designs. As Fig.3 shows, this efficiency remains consistent across the UPS’s entire load spectrum, and achieves a substantial reduction in electricity running and cooling costs.

Conclusions

Overall, modular UPS systems like the example shown meet the exacting requirements of a cloud service provider. With their De-centralised Parallel Architecture and hot swap modules, their availability is extremely high, rated at 99.9999% or ‘six nines’. Modules can be swapped while the system is online without interruption of power or risk to the load. Online efficiency is also high, at up to 96.1%, or better than 99% in Eco mode. And for Cloud service providers and direct business users alike, cost of ownership is exceptionally low, as the system is included on the Carbon Trust’s Energy Technology List for Enhanced Capital Allowances (ECA). This means businesses are able to offset the total cost of the equipment against taxable profits within the year of purchase.